Abstract

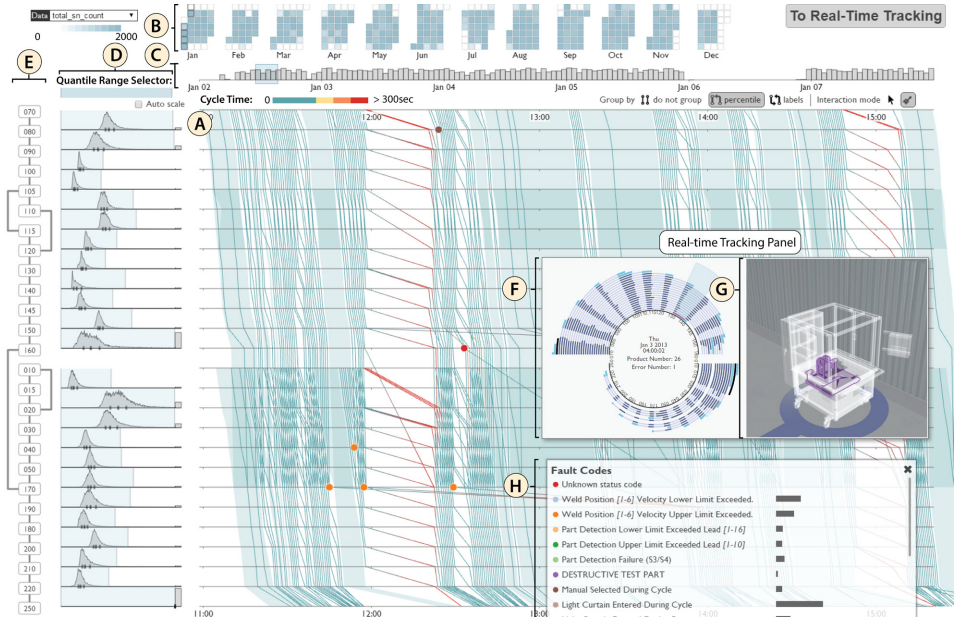

Visual analytics plays a key role in the era of connected industry (or industry 4.0, industrial internet) as modern machines and assembly lines generate large amounts of data and effective visual exploration techniques are needed for troubleshooting, process optimization, and decision making. However, developing effective visual analytics solutions for this application domain is a challenging task due to the sheer volume and the complexity of the data collected in the manufacturing processes. We report the design and implementation of a comprehensive visual analytics system, ViDX. It supports both real-time tracking of assembly line performance and historical data exploration to identify inefficiencies, locate anomalies, and form hypotheses about their causes and effects. The system is designed based on a set of requirements gathered through discussions with the managers and operators from manufacturing sites. It features interlinked views displaying data at different levels of detail. In particular, we apply and extend the Marey’s graph by introducing a time-aware outlier-preserving visual aggregation technique to support effective troubleshooting in manufacturing processes. We also introduce two novel interaction techniques, namely the quantiles brush and samples brush, for the users to interactively steer the outlier detection algorithms. We evaluate the system with example use cases and an in-depth user interview, both conducted together with the managers and operators from manufacturing plants. The result demonstrates its effectiveness and reports a successful pilot application of visual analytics for manufacturing in smart factories.